Wood-aluminium systems at Gutmann: Nature and high-tech, perfectly combined.

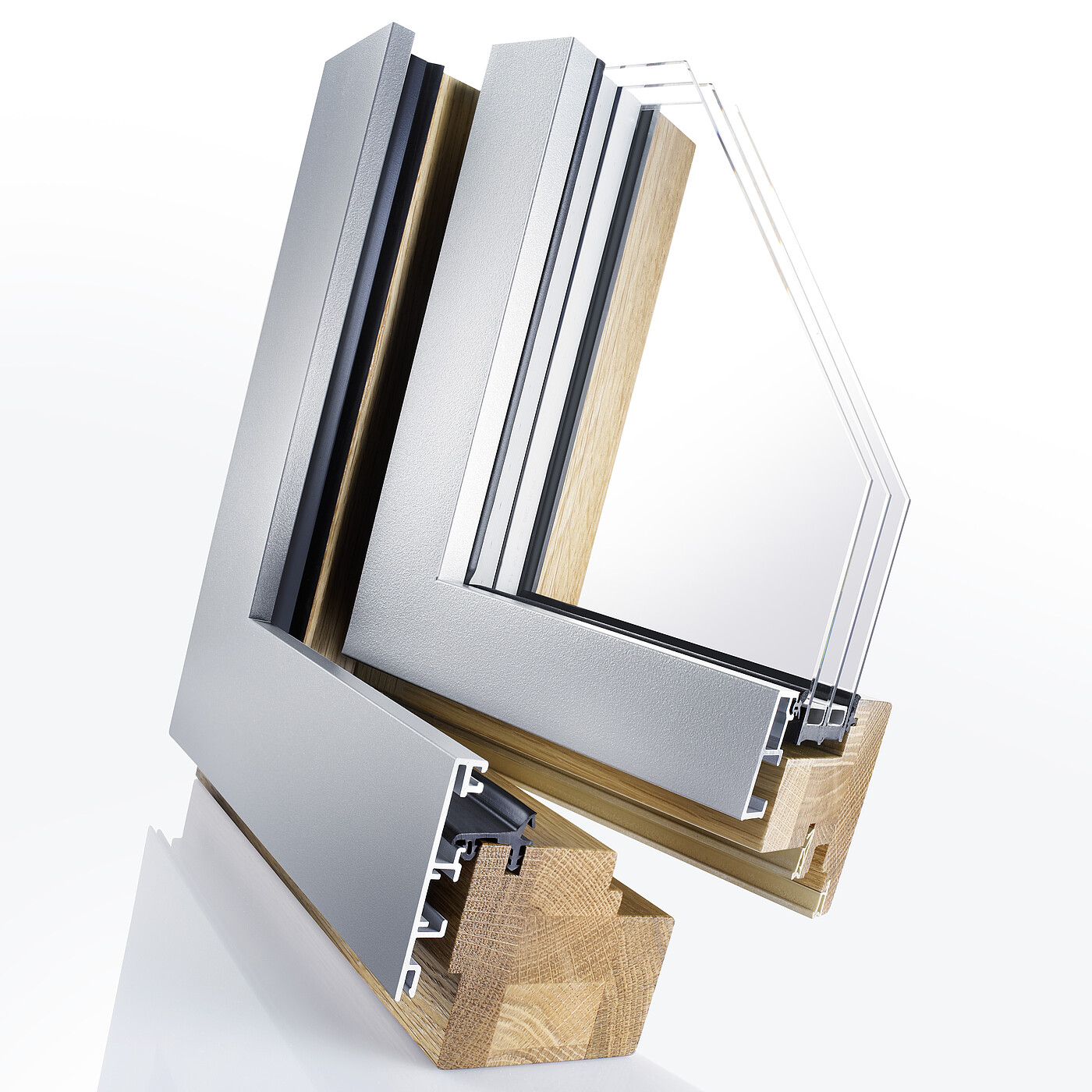

"For us, aluminium belongs to the wooden window like the protective bark to the tree trunk," says Division Manager and wood-aluminium specialist Matthias Dold, explaining the high future potential of wood-aluminium systems at Gutmann. The combination of the valuable and optimally recyclable light metal aluminium and the sustainably renewable raw material wood is convincing in terms of function, design, durability, and diversity as well as ecological and sustainable aspects - and makes wood-aluminium the optimal window of tomorrow.

Wood-aluminium systems are now considered the windows of the future in many places because they offer the best of both worlds: The sustainability and structural warmth of wood, and the robust durability and diverse modern design options of aluminium. Accordingly, the market is currently hotly contested. What is Gutmann Bausysteme's position here and how do you see your future prospects as one of the most renowned suppliers of wood-aluminium systems?

My personal goal in my various positions at Gutmann has always been to make us the best systems house for wood-aluminium systems. In Germany, despite tough competition, we are leading the way in many areas and hold a top position among the top suppliers in terms of both quality level and volume. In Eastern Europe, too, e.g. in Poland, the Czech Republic, Romania, the Baltic states - and until the Ukraine crisis also in Russia - we were able to establish a very good market position relatively early on as one of the pioneers in these countries, initially with rather simple products. Over the years, we were then able to bring our customers in these countries ever closer to more sophisticated products and more comprehensive system solutions. We score points for our particular flexibility because, unlike some other system suppliers, we do not tie our customers down to our complete range, but always support them at precisely the product and value-added level they need. The market is extremely competitive and demanding, which is why we are constantly investing heavily in our company and in innovations so that we can continue to play at the very top.

The greatest possible flexibility is a philosophy that we are, so to speak, inspired by, and the market today demands more and more of it. At the same time, however, this is often associated with major challenges, not only in terms of the wide range of variants of our products, but also in terms of the depth of assembly and the logistics behind it. Another feature is our convincing system diversity to enable our customers to make optimum adjustments to the respective requirements in terms of construction, aesthetics, statics, architecture, sound insulation and many other factors. I think we can claim with a clear conscience to be unique on the market in this respect and to stand out clearly from our competitors. Many window manufacturers who are our partners have today often reached an extremely high level of competence in their products. Accordingly, the customer-specific requirements for our aluminium shells and our component systems, which we develop together in many cases, are also correspondingly high, but often have to meet existing product specifications. Thanks to our intensive involvement with the requirements of the market, we have been able to build up very comprehensive know-how over decades. In addition, we also have our own IFT-monitored test stand, on which our developments are tested and certified prior to introduction. Wood-aluminium is mostly a topic where great individuality is required. Very special and sophisticated solutions are often required here, which must keep pace with current architectural trends. Therefore, when it comes to such special requirements - such as a lift-and-slide door with floor-to-ceiling panoramic fixed glazing - our partners know that they can get such solutions and much more as a mature solution from us. In fact, we are so diverse that the presentation and overview of this diversity alone represents a challenge of its own. Because even the best catalogue is still far from being able to represent the complete scope of all possibilities that we can actually offer.

Our philosophy, especially for wood-aluminium systems, can be summed up in a fairly simple core statement: On the one hand, we want to ensure maximum quality of life in the buildings constructed with our products. And on the other hand, we are concerned with maximum efficiency in the use of resources and energy, both in the production of our products and in their application and use over many years, even generations. In terms of the technical performance of our elements and systems, we are currently demonstrably among the top suppliers on the market, for example in aspects such as thermal insulation and tightness, the importance of which is all the greater now in view of the current energy supply crisis, or in sound insulation or the subject of burglary protection. In addition, we can underline this technical performance with extremely comprehensive verification documentation, which in turn enables us to decisively support the work of our partners and customers, e.g. when it comes to submitting subsidies for the construction of sustainable buildings.

The topic is indeed very exciting because we are currently living in very turbulent times, in an era of great social, economic and ecological change. And here, wood-aluminium can provide very good answers to many pressing questions. On the one hand, for example, there is the major issue of demographic development with strong immigration, which is causing a high demand for living space and shaping the construction industry accordingly. On the other hand, our ever-increasing life expectancy is playing an important role, which is creating a growing demand for comfortable, barrier-free housing that is suitable for the elderly. And then there is also the major megatrend of urbanization, immigration and densification in urban agglomerations, with all the other trends that the topic of "urban living" entails: affordable living space with a high quality of life, as well as constantly rising expectations in terms of design, modernity and individuality, e.g. in surface and colour design, as well as high demands on the technical and architectural performance of window systems. In addition, there has been a particularly strong increase in expectations in recent years with regard to ecological performance, on the one hand with optimum resource and energy efficiency in production and on the other hand with optimum energy values in use. All this considered, wood-aluminium is the window of the future par excellence, if only because of the extremely wide variety of design options, especially in living spaces. In addition to the variety of designs, wood-aluminium can also score points with the variety of technical possibilities, because contemporary construction trends, e.g. in accessibility, security or automation, can be ideally implemented with wood-aluminium.

Wood-aluminium offers convincing solutions for many energy and sustainability aspects: With our wood-aluminium systems, it is now possible to achieve optimum insulation values that are far below the passive house level. Wood-aluminium is therefore just as interesting not only for new buildings but also for the growing field of thermal refurbishment of existing buildings. Added to this are the optimum ecological material properties: As a renewable raw material, wood is now the building material of the future and is also very easy to separate and recycle in the particularly durable wood-aluminium combination after many decades of use. Material separation during deconstruction can usually be carried out very easily directly on the construction site and the CO2 footprint is low: one cubic meter of wood can bind one ton of CO2 from the atmosphere. If the wood is burned, for example, the carbon footprint is balanced, since burning wood only releases as much CO2 as the tree previously absorbed. And aluminium is also almost completely recyclable and reusable without any loss of quality, making it a valuable material in the truest sense of the word. This high sustainability potential of aluminium recycling, which is very important to us, can be seen simply by comparing the energy required for the production of primary aluminium at an average of 16 kW/h/kg and for aluminum recycling at only 0.8 kWh/kg. Our special commitment to the high future potential of sustainable aluminium recycling has long been underscored, for example, by our membership of the A|U|F Recycling Initiative and our current Cradle to Cradle certification of new Gutmann systems. And it goes without saying that we are currently making every effort, and will continue to do so in our future strategies, to keep transport distances as short as possible in the interest of the CO2 balance and generally to keep our company at the cutting edge of all climate balance issues.