Our Technologies

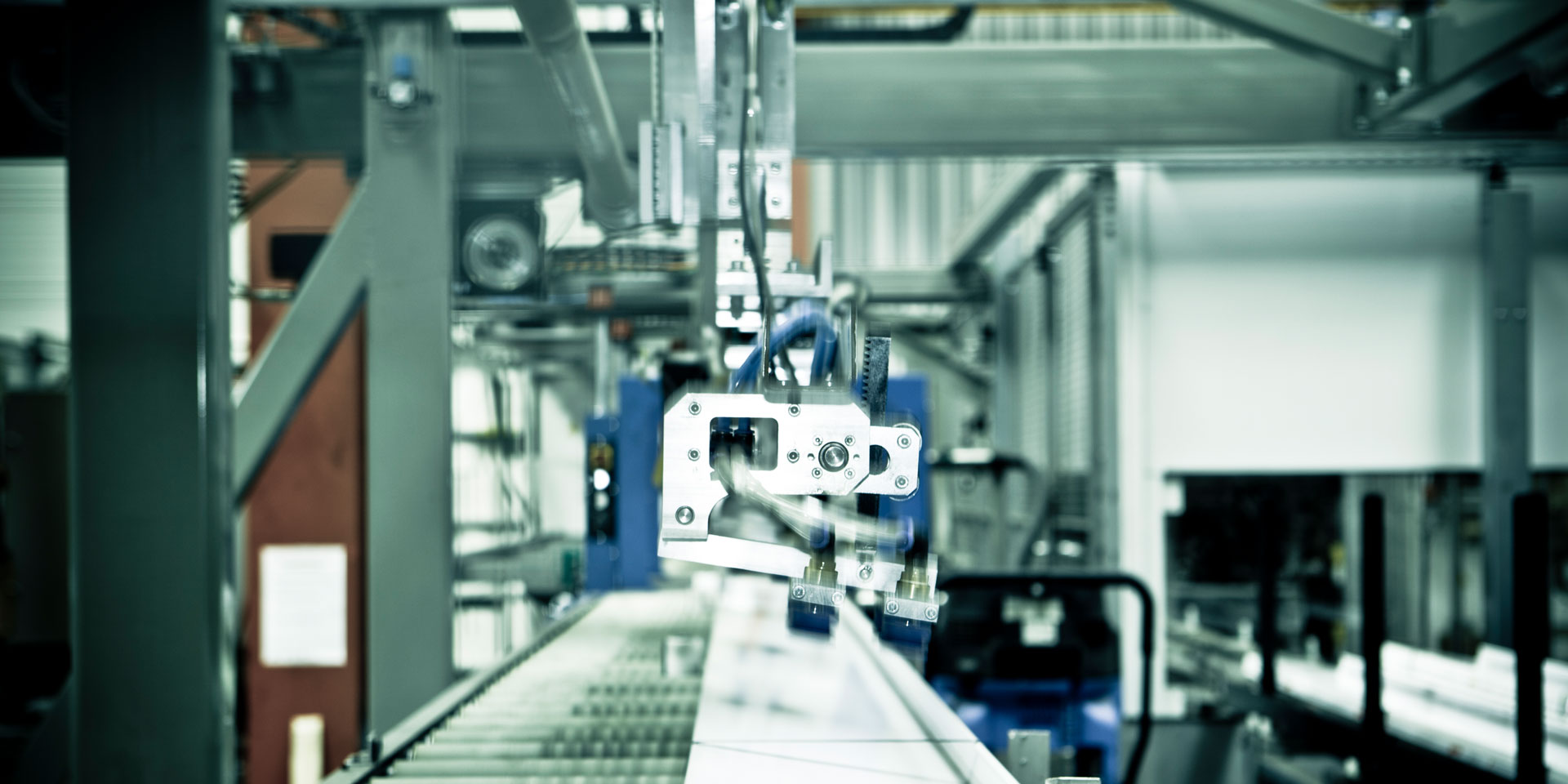

The companies in the GUTMANN GROUP give their customers a variety of the most modern manufacturing methods to choose from. This includes powerful extrusion presses in different sizes, surface finishing machines for powder coating and anodizing as well as a wide variety of facilities and procedures for further mechanical processing. It includes machines for sawing, chamfering, drilling, and punching for shape-cutting on modern 5-axle machining centers as well as devices for folding, embossing, and thermal bonding. Structural component production and manufacturing of complete components including function tests are becoming increasingly important as well.

The GARTNER EXTRUSION GmbH has many years of experience as a supplier for composite structural components for curtain wall projects. Some of those include major projects such as the Bank of China (Hong Kong), the Deutsche Bank building (Frankfurt), Taipei 101, and the Hamburg Philharmonic Hall, just to name a few. Here, clients receive much more than simply the delivery of an aluminium profile: Innovative technology combined with capacities for large projects, long warranty periods, and a high level of flexibility.

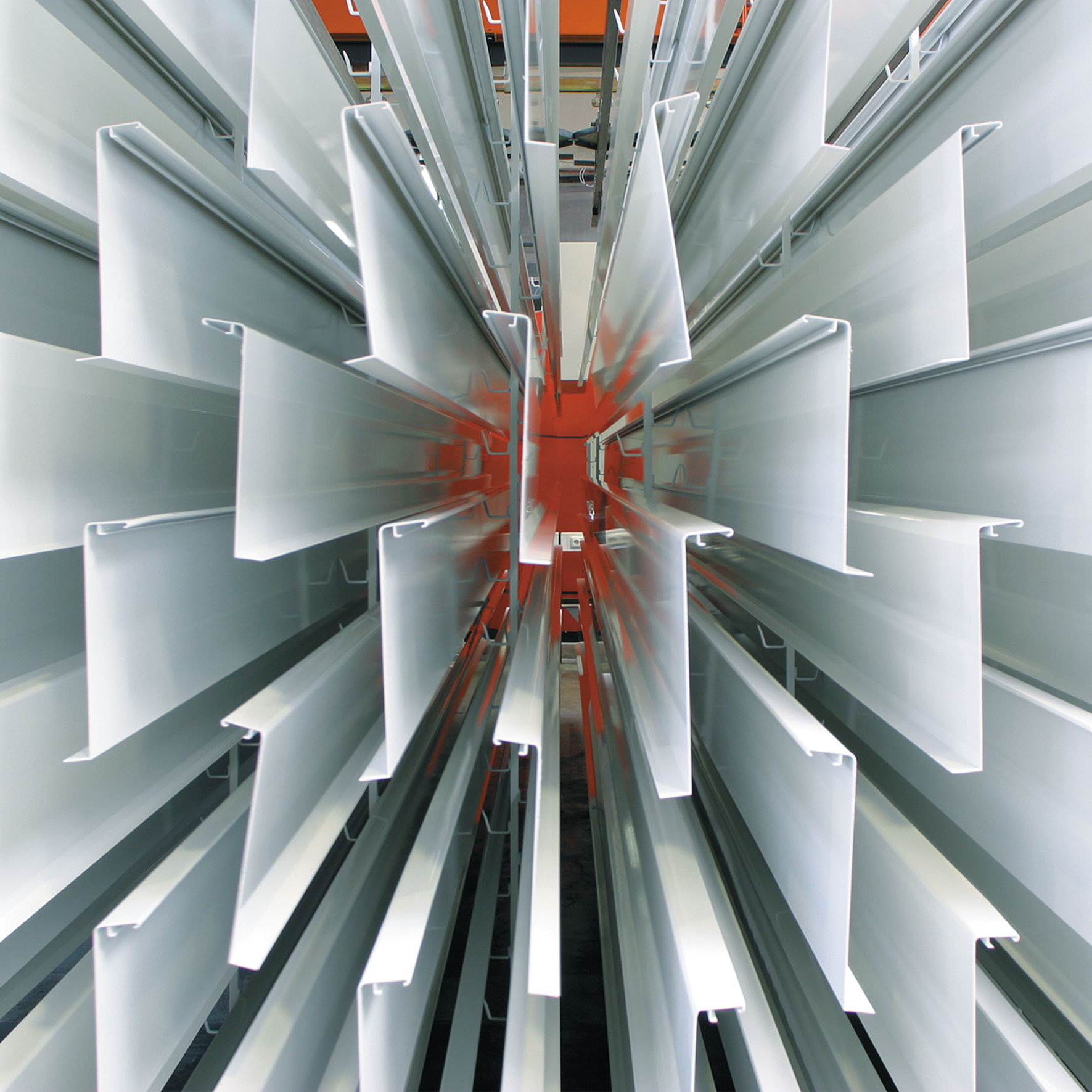

Extrusion

Extrusion allows even complex shapes of aluminium profiles to be manufactured. It is what makes this process so powerful.

Surface finishing

Some procedures in which aluminium surfaces are treated can not only alter the appearance of the metal but also improve surface quality and corrosion resistance.