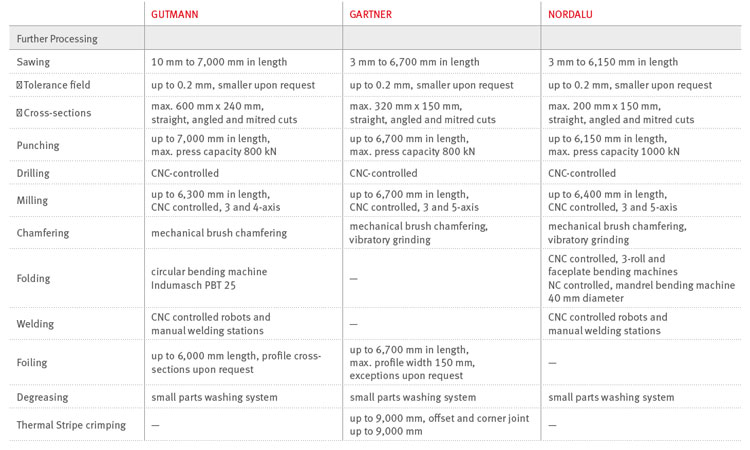

The companies in the GUTMANN Group are well equipped to provide it: Processing on modern, high-performance CNC machines is a standard for us just as much as sawing, chamfering, milling, punching, drilling, sanding and thread cutting are. The GUTMANN Group is furthermore prepared to work with special requests regarding mechanical processing.

This includes welding, soldering, gluing, riveting, screwing, bending and joining. The joining method is used especially for extrusion profiles with plug connections, hinging or snap joining. If aluminium is combined with other materials, many of the abovementioned methods may be used as well.