A concept for millions

Expansion of Terminal 2 at Munich Airport

In order to relieve the traffic at Terminal 2 (T2) at Munich Airport, a new satellite building is currently being built in the eastern apron area which will increase the handling capacity by eleven million passengers per year. The satellite terminal can be reached from Terminal 2 through an underground, fully automated personnel transport system, the basic elements of which had already been set up in rough construction at the time of the construction of T2.

Focus on energy - MUNICH AIRPORT

Sunblind insulating glass panes with a Ug value of ≤ 1.1 W/(m² K) and a g-value of ≤ 0.28 were used in the façade. In combination with the interior steel façade with its single glazing, the "double façade" contributes to the energy-related optimization of the building envelope. At the same time, this double façade space is accessible to travellers and is used for enclosing the three passenger levels.

Architecture for intuitive orientation

The design criterion was to foster recognition and thus the connected association with T2. This means that the satellite fits in not only visually but also functionally with the overall image of the airport. The strategic use of light and clearly structured spaces optimises orientation for travellers. Outstanding air-conditioning and acoustic conditions support this aspect even more and enhance the quality of the time spent at the airport. The market area with integrated tower which is used as the control centre for the aprons, is the core of the satellite. At one and the same time, it is not only a meeting place but also the centre of the retail and food service area. The huge glass façade provides travellers with a panorama view of the airport apron.

The architects at K+P Koch+Partner have placed great value on enabling passengers and visitors to move independently through the spaces without losing track of where they are, despite the dimensions of the terminal. The Munich architecture firm relies on an interdisciplinary team of architects, urban planners and interior designers, construction engineers and interior decorators, for which traffic structures are one of the focal points. The forty years of experience of K+P Architekten und Stadtplaner GmbH were put to good use for the construction of Terminal 2 and the addition of another storey and the expansion of the associated luggage sorting hall to a satellite terminal.

Extension with special solution

Work is being undertaken on the extension of the T2 while air traffic operations continue. This is a great challenge for building logistics, because airport operations must be maintained during the entire period of construction.

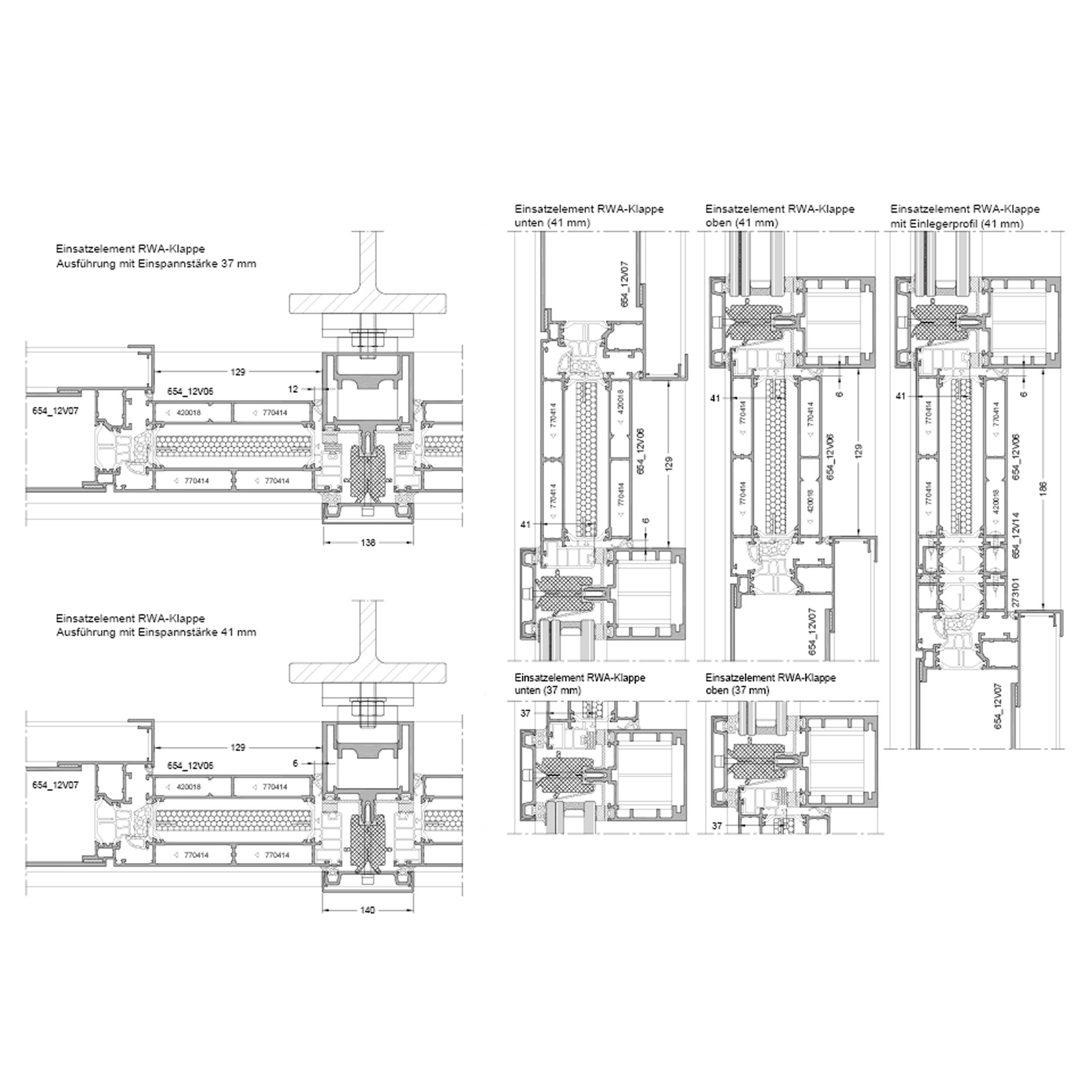

The project presented not only organisational but also technical challenges for the participants. Due to the special requirements with respect to tightness, the large window pane formats and the loads to be moved, no standard system could be used. Dobler, the metal construction company charged with the execution of the project, had already implemented large parts of the façade at Terminal 2 and, working together with GUTMANN as system provider, developed a special façade design for the satellite areas. "We received support from GUTMANN in many ways in the transition from the theoretical to the practical design stages: including during production and through the correct execution of the installation", explains Jürgen Schäfer, Project Manager at Dobler. The system features view widths of 70 mm and special steel and aluminium cruciform joints. The construction bears a maximum weight of 600 kg with dimensions of 2.8 x 4.8 metres.

A total of 17,000 m² of the mullion-and-transom façade was installed. In addition, the 950 installed RWA flaps and air vent openings measuring 2.4 x 1 metres also represented a special development.

"GUTMANN's commitment convinces. The implementation of the desired concept was optimally devised and well-presented. It was clear that someone had really given this some thought. The delivery proceeded silently and the material for the individual batches was always available on time. There was actually very little we had to take care of ourselves", declares Schäfer.